Shielding brick and fire block are both sorts of refractory bricks used in high-temperature applications, however they differ in their structure, density, thermal conductivity, and planned usage.

Right here are the major differences between protecting brick and fire block:

Composition:

Shielding Brick: Protecting bricks are generally made from lightweight refractory products such as broadened clay, shale, or perlite. They contain a high percentage of air or gas-filled spaces, which provide reduced density and excellent thermal insulation buildings.

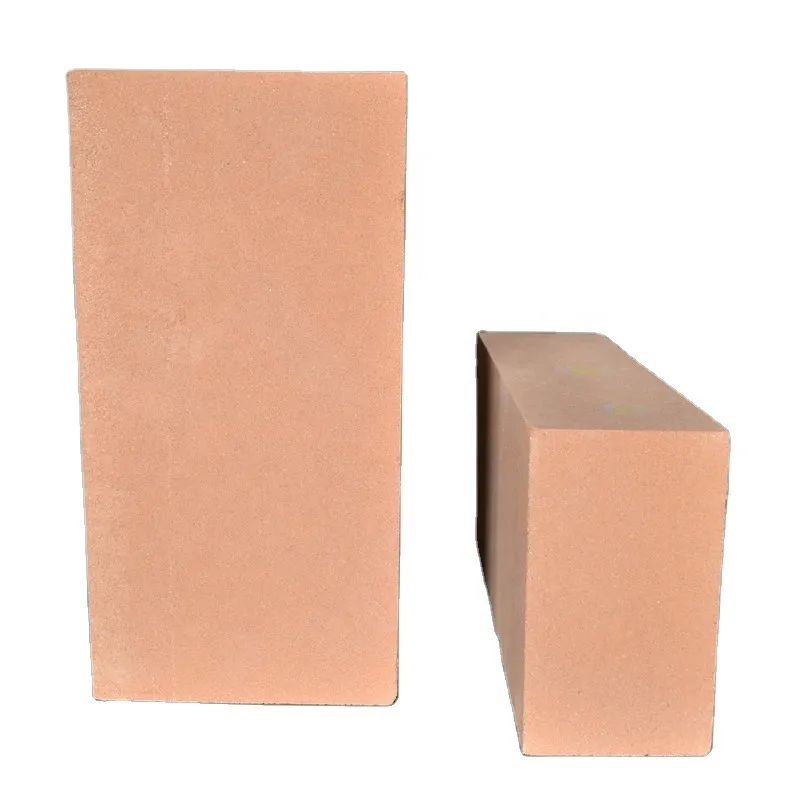

Fire Block: Fire bricks, also known as refractory blocks or heat bricks, are made from dense, high-alumina, or silica refractory materials. They are designed to hold up against heats and mechanical stress and anxieties, making them ideal for usage in heating systems, kilns, and other high-temperature settings.

Thickness:

Insulating Block: Insulating bricks have low thickness because of their porous structure, which consists of air or gas-filled voids. This low density results in light-weight bricks that are easy to handle and install.

Fire Brick: Fire blocks have high thickness and are more strong and hefty compared to shielding blocks. The thick framework of fire blocks gives them better strength and resistance to mechanical abrasion and thermal shock.

Thermal Conductivity:

Protecting Block: Protecting blocks have excellent thermal insulation properties as a result of their reduced thermal conductivity. The air or gas-filled gaps in shielding bricks act as obstacles to warm transfer, reducing warmth loss and improving power effectiveness in high-temperature applications.

Fire Brick: Fire blocks have greater thermal conductivity contrasted to insulating bricks. While they offer thermal insulation to some extent, their main feature is to hold up against heats and shield bordering structures from heat.

Planned Usage:

Insulating Block: Protecting blocks are largely utilized for thermal insulation in applications where lowering warm loss is crucial. They are commonly used in kilns, furnaces, boilers, and various other high-temperature devices to improve power effectiveness and lower operating expenses.

Fire Block: Fire blocks are designed for use in applications where high-temperature resistance and mechanical strength are required. They are generally utilized to line the interior of heating systems, kilns, fire places, and smokeshafts to protect structural components from heat and abrasion.

In summary, shielding bricks are lightweight refractory bricks with superb thermal insulation residential or commercial properties, largely used to decrease heat loss in high-temperature applications. Fire blocks are dense, high-temperature refractory bricks designed to hold up against extreme heat and mechanical tensions, typically utilized to line furnaces and various other high-temperature tools.