With Hy-Pack® channel squeezes, you’ll be succesful of discard higher solids content material cake than you would with vacuum channels, belt presses or rotators. A channel press is among the most seasoned and most confided in bits of dewatering gear. It’s utilized for wastewater treatment across a major determination of businesses and purposes.

Cake thickness influences the penetrability of the filtration media and the filtration cost.

Testing for the specific muck sort should be performed to find out the ideal cake thickness. At times the spot filtrate recuperation is significant, it could be fundamental to present a cake washing step. There are numerous actual partition processes very much like the belt channel press utilized for dewatering, along with axes, vacuum-circle channels, and the plate and body channel press. At the point when in likeness with other pressure channels, belt channels use relatively decline pressures. In spite of the fact that rotators have lower dampness content material, decline costs and simpler activities in coal tails handling, belt channels will generally make substantially less commotion and have a lot quicker startup and closure occurrences.

The conveying of the medium into the channel press is finished through an amount and strain controlled free-stream siphon. During the underlying step of the channel press dewatering cycle, the filtrate move from a major press can be as a ton as 10,000 to twenty,000 gallons each hour. During this time the cake offices of the sludge press channel press assemble the main measure of slime solids. As the chambers transform into continuously more brimming with muck solids, the pressure contained in the channel press plate pack rises and the filtrate stream rapidly diminishes. One of the most troublesome issues at present is the removal of oozes in squander cure. The channel press course of results in drier ooze that has affirmed to be a compelling answer for this issue.

While considering costs comparing to capital stuff, molding merchants, transportation and treatment of molding representatives.

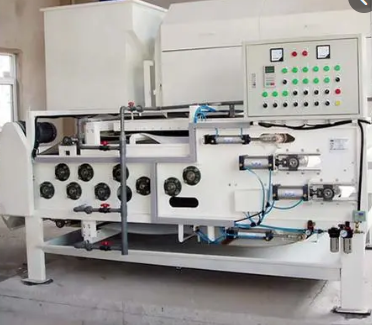

Prior to dropping all the strategy down to the accompanying stage, data plates assist with setting the muck towards the focal point of the belt ensuring nothing is crushed out the side of the channel. After this, a second gravity thickener rehashes the cycle before slime is taken care of solidly into a pressing zone. Here we presently have a Sludge Filter Press which is provided with 35 chambers or 36 polypropylene channel plates that have a plate configuration of 800 x 800 mm. Because of the cake thickness of 30 mm this closures in a press content of 563.5 liters and is expandable to 644 liters.

Items exemplify dewatering tables, drum thickeners, bushel axes and outward decanters. Different kinds of dryer are also realistic, along with convection drum dryers and fluidised sleeping pad… A channel utilizing flush plates and approaches set up for by means of washing has separate slurry feed and wash feed ports, and both the indistinguishable or isolated release ports for filtrate and wash alcohol outlet. Motorized channel presses are generally utilized from slop dewatering because of the enormous assortment of critical cycles expected in a predefined time span. The channel press basically contains changed chamber channel plates mounted upward on and between two sidebars or suspended from an above help shaft. The help pillars or sidebars are connected toward one side to a set head, also called a feed head, and on the opposite finish to a completion head.