Porosity and cake dampness contents are essentially lower than those acquired with regular pressure channels, thusly, filtrate rebuilding is high. Filtration is directed at a feeling of anxiety the spot the cake is created as a hard floor dry, serious areas of strength for knot. Cake dealing with is altogether streamlined contrasted with conventional pressure channel sweets, that are now and again glue like and routinely surface wet.

The chambers made by the plates are full up with the slurry, the material and the high tension dry the biscuits, speedier and higher. The utilization of ECOFILTER® in thickening on channel presses and belt channel presses advances the limits of your set up and kills obstructing of the supporting materials. The FP is the one mechanical thickening or dewatering mastery that is confined to batchwise activity. Reusing Scrap and waste handling apparatuses for the steel business, scrap yards and waste taking care of harvests. To further develop efficiency in your mine, we offer a strong arrangement of computerized arrangements and administrations that interface, screen and upgrade execution of your property.

The filtration cycle additionally on this case is naturally overseen …

Straightforward furthermore implies the channel press comprises of recessed chamber plates, connected together by chain, and a shaker framework comprising of pneumatic chambers, all ordinary with the MEGALITH channel press. Dewatering by high/pressure skill implies the following drive to drive or pack the channel cake, arriving at a dryer channel cake as low as 10% remaining dampness, offering back as a ton as 98% water to the interaction.

This prompts solid and dependable mechanization capacities with decline torque, less control valves and less intricacy than multi-chamber plans. McLanahan’s Overhead Beam type prompts faster opening and shutting for more prominent creation and higher cake send off in tailings applications. It likewise offers greater plate openings for better cleaning and upkeep access. McLanahan’s Side Beam type is intended for concentrates and more modest tailings capabilities though giving quick plate/fabric expulsion.

- A 10 cubic foot press at 32mm cake has 211 square feet of surface region for a 0.047 cf/sf ratio.

- The close participation brings about progressive choices with which MSE separates itself from the unadulterated extra components market via brilliant quality – and this for quite some time now.

- Such plaques moreover comprise of holes whose arrangement is the slop taking care of ducts.

- The KFP-C sort Clean System incorporates a reasonable, aseptic, trickle free filter.

- While one 3″ AOD siphon can send 203 gpm, the working envelope can be on the sting of the curves.

On the off chance that cake washing, terminal strain is around 50 psig, in some other case terminal pressure is around 100 psig. When the pressure has been feeling quite a bit better for both the layers and the slurry channel, the press is ready to open and for cake send off to continue as depicted in Step 13 of the Recessed Chamber Test. With four channel aspect decisions and the possibility to add channel modules, the Verti-press covers a large number of capacities and applications. When ideal cake top is reached, a stomach precisely presses the channel sleeping cushion, delivering the fluid anyway not crush the solids. Utilizing astute cycle controls, the slurry is taken care of into the channel though being checked for the ideal cake top. The gigantic benefit of leasing a channel press is it can generally squeeze into your functional spending plan requiring No Capital Investment.

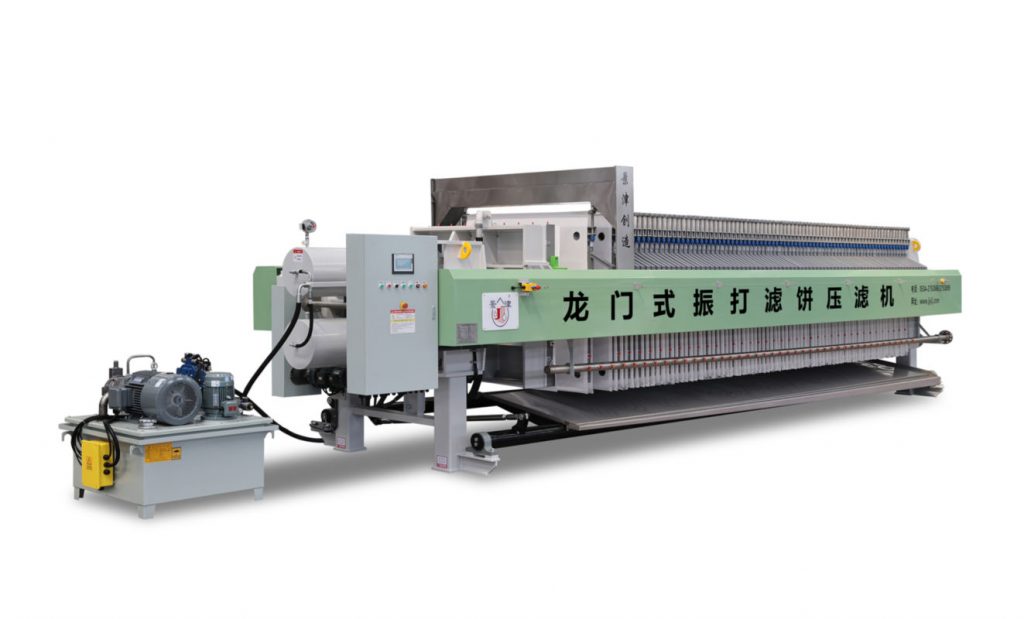

That is the way to progress for Matec® channel squeezes, which use tensions of 21 to 30 bar to manage even basically the most troublesome and debilitating to manage slurries, independent of the area or application. This long authentic past of improvements’ permitted the channel presses of today to achieve filter press fundamentally decline energy and upkeep costs contrasted with their belt press and rotator partners. Truth be told, the whole working filtration an incentive for a channel press can without much of a stretch be 1/6 the expense of what it very well may be for a belt press or rotator. Jingjin has numerous talented and experienced senior specialists, and could introduce proficient fluid strong partition answers for our possibilities.

The decision of the best siphoning framework is critical to proficiency and working costs.

The item scope of ANDRITZ above channel presses contains chamber and layer channel presses up to an element of two,500 x 2,500 mm and an area of 2,000 m². For press limits of a hundred 25 cubic ft or less, the twofold Air Operated Diaphragm siphon is extraordinarily fitted to channel press tasks. As the solids build up all through the press, the protection from circle will increment and the flow expense through the press diminishes.

Channel squeezes offer a broad scope of use, surely one of its primary recommendations is the adaptability to give a major channel space in a relatively little impression. Surface space out there is viewed as quite possibly of the most essential aspect in any separating cycle, since it expands channel flow expense and limit. A typical aspect channel press gives a channel area of 216 m2, while a standard belt channel just presents approximately 15 m2. These days channel presses are generally utilized in numerous enterprises, they would furthermore create various kinds of squanders. Hurtful squanders like harmful synthetic from color enterprises, as pleasantly as microbe from squander stream might aggregate inside the waste biscuits; subsequently the necessity for treating those squanders could be unique. Subsequently, before release squander stream into the setting, utility of post-treatment would be a significant sanitization stage.

With the crosshead completely withdrawn, a uniform hole is opened between each plate, permitting all chambers to purge. The crosshead then, at that point, returns the plates to filtration place the spot locking chambers anchor the carriage. Shutting pressure is used to the plate stack and slurry feed continued. Whether you use in the mining, sand and totals, C&D squander reusing, modern sands or natural areas we’ve a channel push on your utility.